It’s time to replace your deck, and you need to consider your options – MOST of which will revolve around what color the composite decking will be, whether you should use cable rail or aluminum rail, and whether you’ll include lights in your budget for that perfect anytime outdoor oasis.

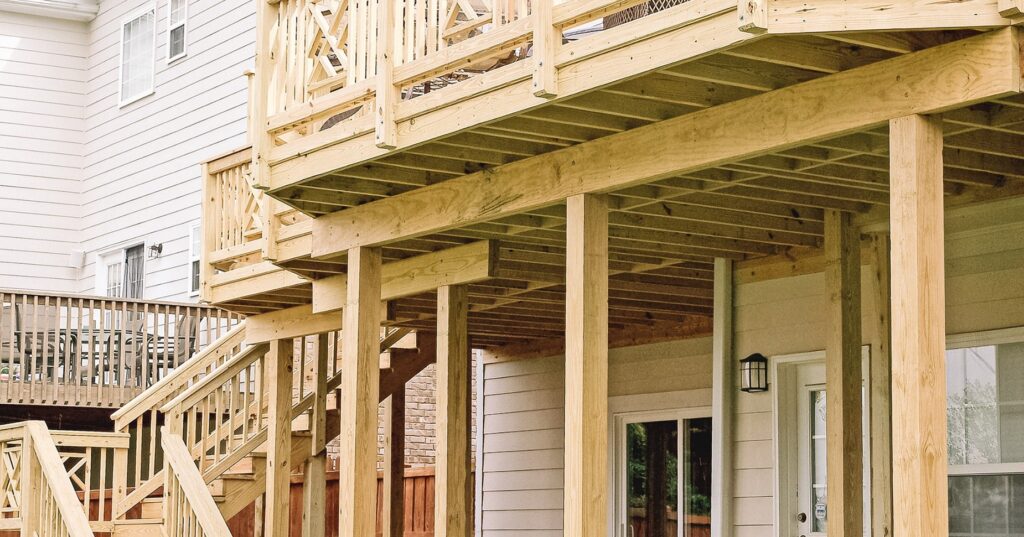

It’s easy to create the perfect result in your imagination, and your deck can be great if attention is paid to the bones of your structure, and consideration is made on how to properly plan construction of the deck frame.

4 Types of Deck Frame Materials To Consider

Once you’ve created the plans for building a deck frame, and you have an idea of how your project is going to be laid out, it’s time to consider what material you are going to use to support your structure. Here we’ll outline four types of material that could be considered for your deck, which range in price, quality, durability, and ease of installation.

Not all material used to frame decks are created equal, however. Some things to consider when selecting your material are:

What is your budget?

-

- The more refined your lumber is, the more it is going to cost.

How concerned are you with your lumber’s appearance?

-

- Most pressure treated wood produced today is graded #2 which is standard structural rating, but not necessarily a finished board look.

-

- Most lumber mills treating wood have a ground contact grade lumber available, which is used for posts, and generally any material wider than 2×8. If your deck is low to the ground, touches the ground, or is exposed to water for prolonged periods of time, consider this treatment required.

-

- Some mills will offer a #1 treated lumber. This product is generally graded for appearance, and will generally have much fewer blemishes, knots, and barked edges than #2. The structural rating advantage of his material is minor or negligible when compared to #2 – but will generally look better.

Do you want (and need) your members to be uniform?

-

- Although it is generally made to order, kiln dried treated lumber or KDAT is available in many areas of the US. If you are looking for a product that is going to have less tendency to change shape once it is installed, this is your best option because most moisture has been removed from the board.

How long do you want your frame to last?

-

- Materials made from natural fiber are not going to last forever when exposed to the elements. Steps can be taken to mitigate water, and minimize exposure to weather, but no wood product is guaranteed for this reason. Most wood frame decks will last at least 15 years with a wood frame if built well.

-

- Man-made materials produced today are truly incredible – but each has drawbacks, and although today’s warranties on such products are generous – changes in landscape, extreme weather events, can cause changes in a structure that can’t be accounted for. If you want a deck that will last decades, almost for sure, choose a man made and engineered product for your frame.

Pressure Treated Lumber ($-$$ | DIY/PRO)

The most commonly used deck frame material is pressure treated lumber, which for most of the United States is a staple found in nearly every lumber yard and home improvement retailer’s building materials department. This product is the standard when it comes to building structures outdoors, or where they are exposed to moisture, sunlight, and the extreme elements brought on by seasonal weather patterns.

Most pressure treated wood is made by injecting preservatives into Southern Yellow Pine, Douglas, or Hemlock Fir with extreme pressure, which will give them a chance at resisting weathering elements for a great deal of time, and are durable against the elements often in excess of 10-15 years.

Treated wood is heavy when it is recently processed, easy to cut, and receives fasteners of all types, like structural screws, nails, staples, etc. Because is it is widely available, pricing on this type of material is generally the least expensive option when selecting wood for your deck frame.

Treated LVL and Beams ($$$ | PRO)

LVL, or treated laminated veneer lumber is an engineered product made from layers of wood and glued to near exact specifications for any construction project. Engineered wood can be mass produced and replicated with precision, so there is no need to worry about joist developing a crown that causes your decking to appear warped or sag.

Another benefit of using LVL’s is the spans of members can be marginally wider than with treated wood counterparts. Getting your hands on treated LVLs can be difficult as they aren’t readily available in every market. If you are interested in pricing and availability in or around the Kansas City or Wichita metro areas, we can source PWT Treated LVLs with a few days lead time.

Composite Fiberglass Reinforced Lumber ($$$$)

A somewhat new product to the decking world is a composite lumber, that is reinforced with fiberglass made by WEARDECK™, an Owens Corning company. This is a great product if you want something that can stand up to the harshest environments, and will be more durable than a real wood product.

WEARDECK™ is a wood alternative that boasts a rotproof, rustproof, and complication-free option for a deck frame that is going to keep your deck strong, safe, and straight for decades to come. WEARDECK™ offers a warranty that extends through the lifetime of the original purchaser’s ownership if installed on a residential property, and 25 years for commercial applications.

Evolutions Steel Deck Frame by Fortress Building Products

Using a metal deck frame like the Evolutions Steel Framing system from Fortress Building Products is a beautiful, modern, and perhaps the most sturdy way to support your deck. Every member is exactly the same, and all are painted with a textured powder coating that makes them beautiful, durable, and resistant to all of the elements, and rust.

This steel deck framing is a customizable, and versatile option for designers and builders that want to create a strong and beautiful project. Steel framing members are lighter and stronger per foot, do not change shape or shrink/expand, and require fewer support posts or members, and will span longer lengths than other comparable engineered materials. If you want something to last a VERY long time, this is your product.

Once you’ve decided how you want your deck frame to look, whether you want it installed or you want to install it yourself, and you’ve understood how long it will probably last, you can make your choice. Note that most decks today are built using pressure treated lumber, few are built using engineered wood. Fiberglass composite and steel frames are gaining popularity where budget allows, and where extreme conditions like saltwater coastal environments demand high performance products, but they are still far and away the minority of structures built for decks.

Here at The Deck Supply, we believe in all of these products for your frame, and want to help you make the best decision for your project. Visit one of our showrooms or give us a call and we’ll provide samples and information that will help you choose the right frame for your deck.